Forecast of the Development of Automotive Lighting Manufacturing Equipment

The global market size is projected to reach $50.13 billion by 2030. This trend not only defines the future of automotive lighting products but also points to a clear path for the development of its manufacturing equipment.

I. Core Development Orientation: Flexible and Precision Manufacturing for “Smart Lighting Factories”

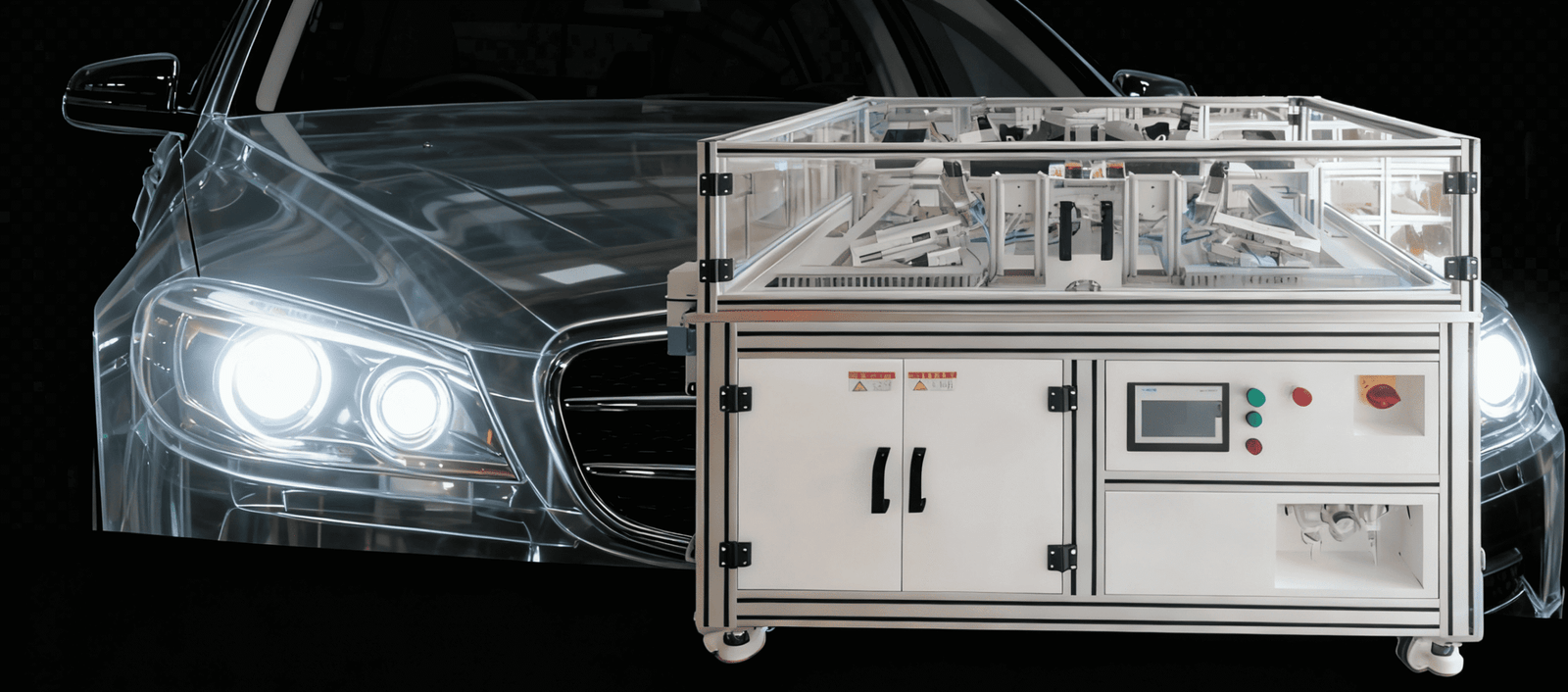

Future automotive lights will no longer be simple optical components, but rather “intelligent interactive terminals” integrating precision optics, electronic control, software algorithms, and personalized design. Therefore, manufacturing equipment must adapt to this fundamental shift in product attributes.

- Adapting to Light Source Technology Trends: Focusing on the Precision Assembly and Testing of LED/OLED/Mini-LED/Micro-LEDD

- Supporting Digital and Intelligent Functions: Strengthening Optical Design Verification and Intelligent Calibration Systems

- Meeting Personalization and Design Upgrade Needs: Developing Flexible and Rapid Changeover Molds and Processing Technologies

- Empowering New Intelligent Interactive Functions: Establishing a Dedicated Manufacturing Chain for Projection and Display Modules

II. The Supporting System Throughout: Automation, Informatization, and Green Development

- Automated and Intelligent Production Lines: Constructing fully automated production lines from chip mounting and optical component assembly to final assembly and functional testing. Extensive use of machine vision for online quality inspection reduces human error and improves production efficiency and consistency.

- Industrial Internet and Digital Twins: Utilizing IoT technology to collect equipment data and build digital twin factories. This enables real-time monitoring of production status, predictive maintenance, and process parameter optimization. Production data can also be fed back to the design end, forming a closed loop and accelerating product iteration.

- Green manufacturing technology: Develop low-energy production equipment (such as energy-saving injection molding machines), use environmentally friendly processes (such as water-based coating spraying and dry coating), and design equipment and processes that facilitate the recycling and dismantling of lamp sets, in response to global sustainable development requirements.