Description

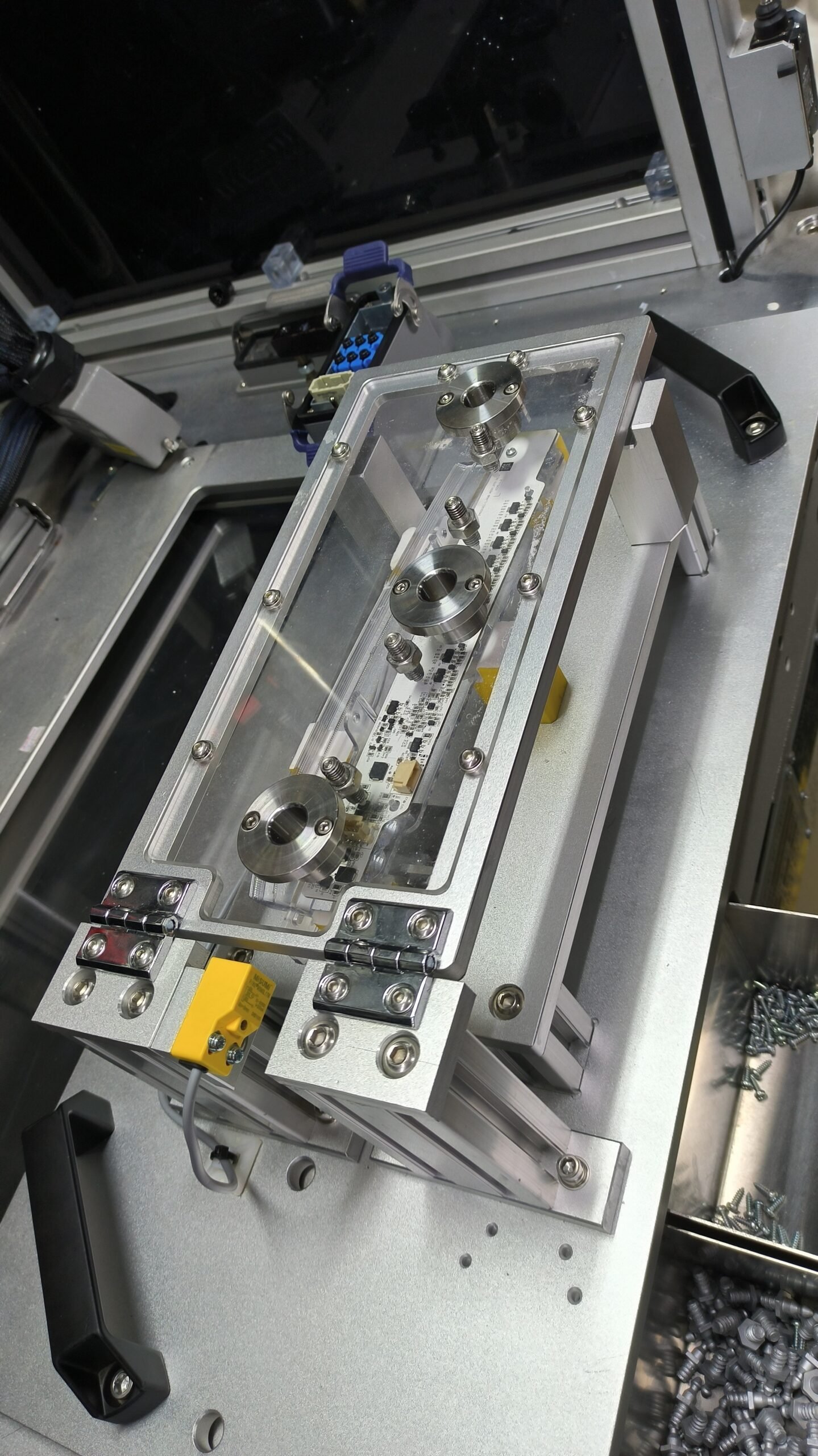

This fixture is specifically designed for tightening automotive headlight screws, achieving a positioning accuracy of ±0.01mm and adaptable to the screw hole positions of various vehicle models. It utilizes a high-strength aerospace-grade aluminum base material with scratch-resistant rubber pads, ensuring rigidity while preventing scratches on the headlights. Its modular quick-change structure supports multiple screw sizes, enabling efficient assembly and disassembly and improving tightening efficiency by 50%. Combined with a torque feedback system, it ensures consistent screw tightening, significantly reducing the rate of missed or over-tightened screws, making it a core piece of equipment for efficient quality control in automotive headlight assembly lines.

Inspection-tools-used-with-testing-equipment-300x300.jpg)

Reviews

There are no reviews yet.