Description

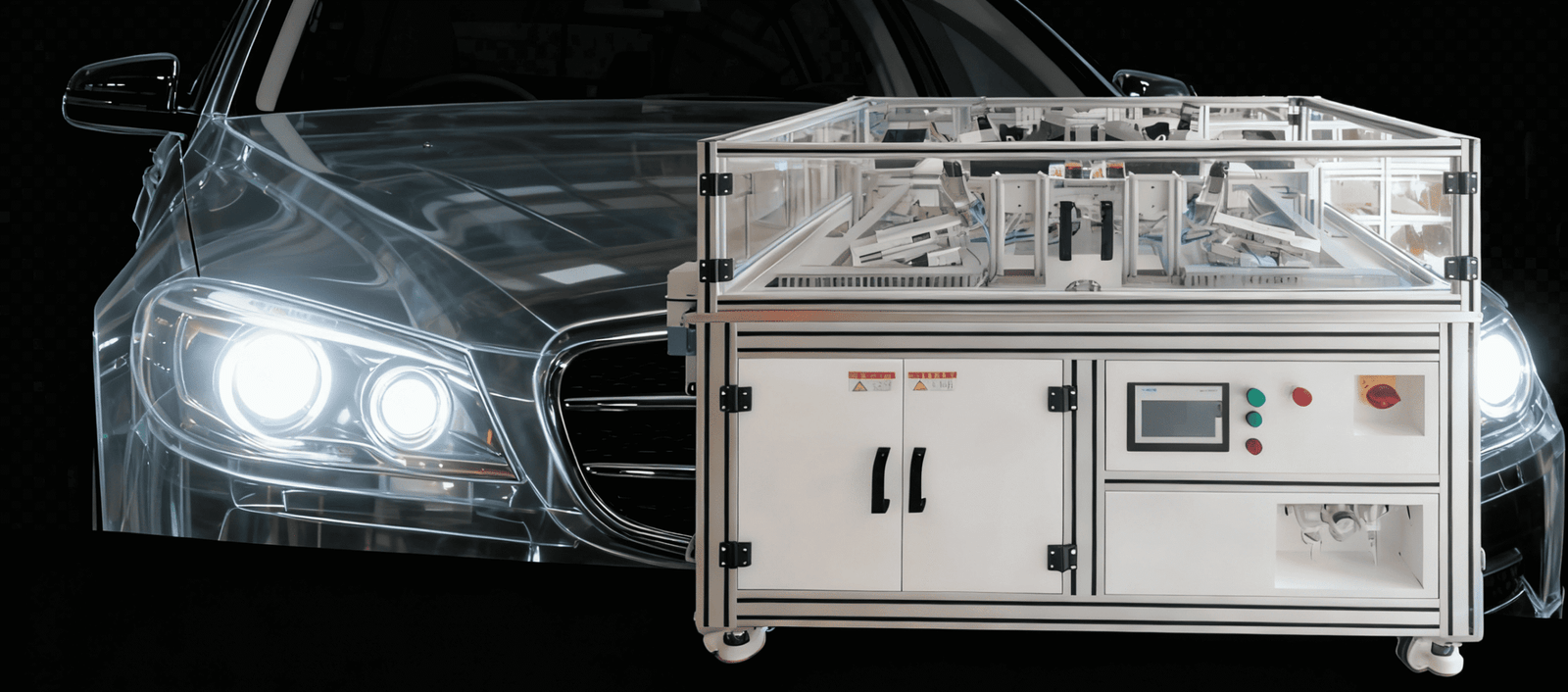

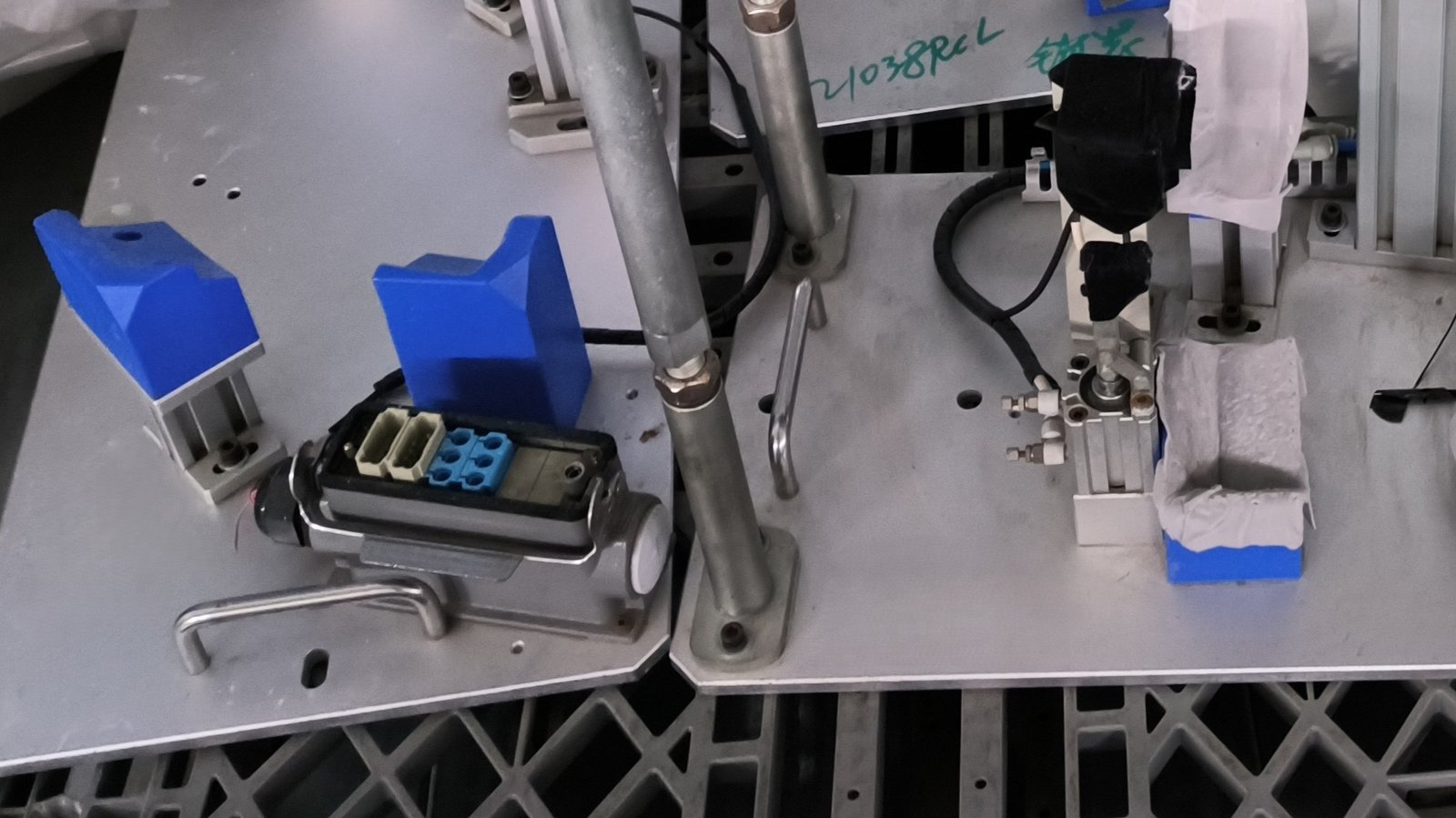

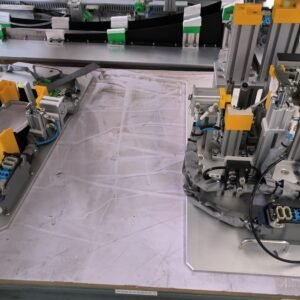

This fixture is specifically designed for the precise press-fitting of plastic components for automotive lighting in passenger cars, commercial vehicles, and new energy vehicles. It is suitable for assembling various automotive lighting plastic parts such as lamp covers, housings, and lenses. Utilizing an aerospace-grade aluminum base material with a scratch-resistant POM coating, it achieves a positioning accuracy of ±0.02mm. Equipped with a servo drive system and pressure displacement monitoring function, it enables non-destructive press-fitting and prevents deformation.

The modular quick-change structure supports rapid model changeover, adapting to common scenarios across multiple vehicle models and improving press-fitting efficiency by over 40%. Strictly compliant with IATF 16949 and ISO standards, it has an IP67 protection rating, withstands high and low temperature environments, and effectively ensures consistent press-fitting of automotive lighting plastic parts, reducing assembly defect rates. It is a core piece of equipment for efficient quality control in automotive lighting production lines and assembly lines.

Reviews

There are no reviews yet.