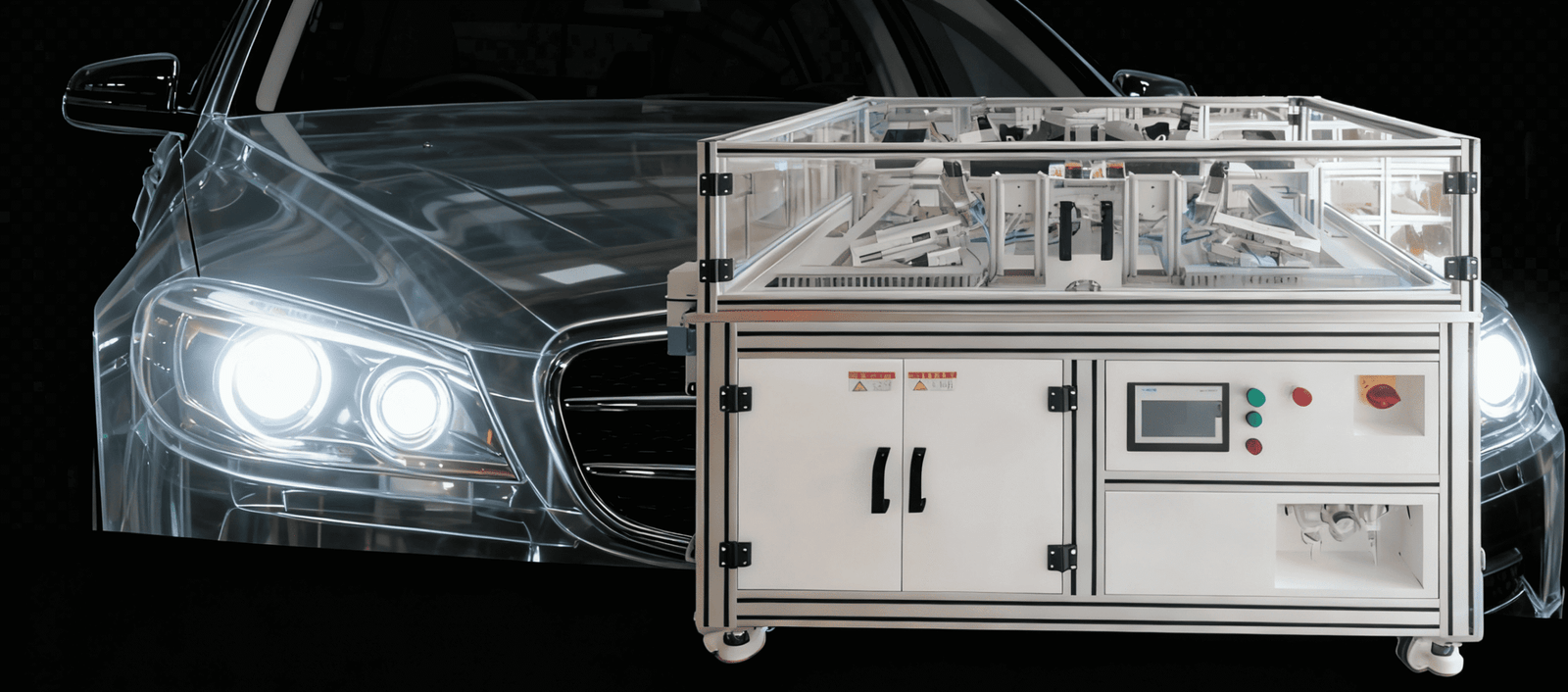

Description

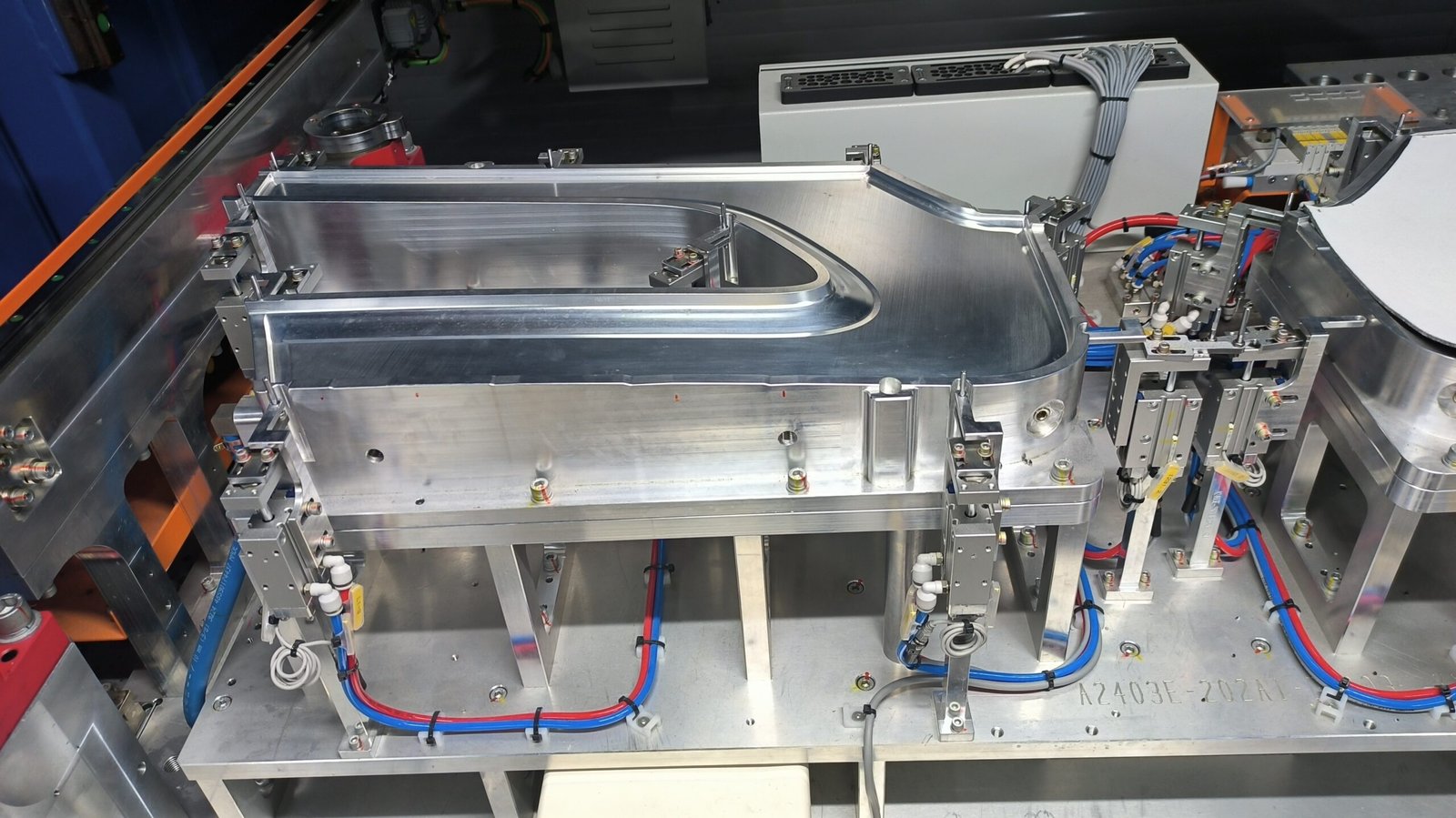

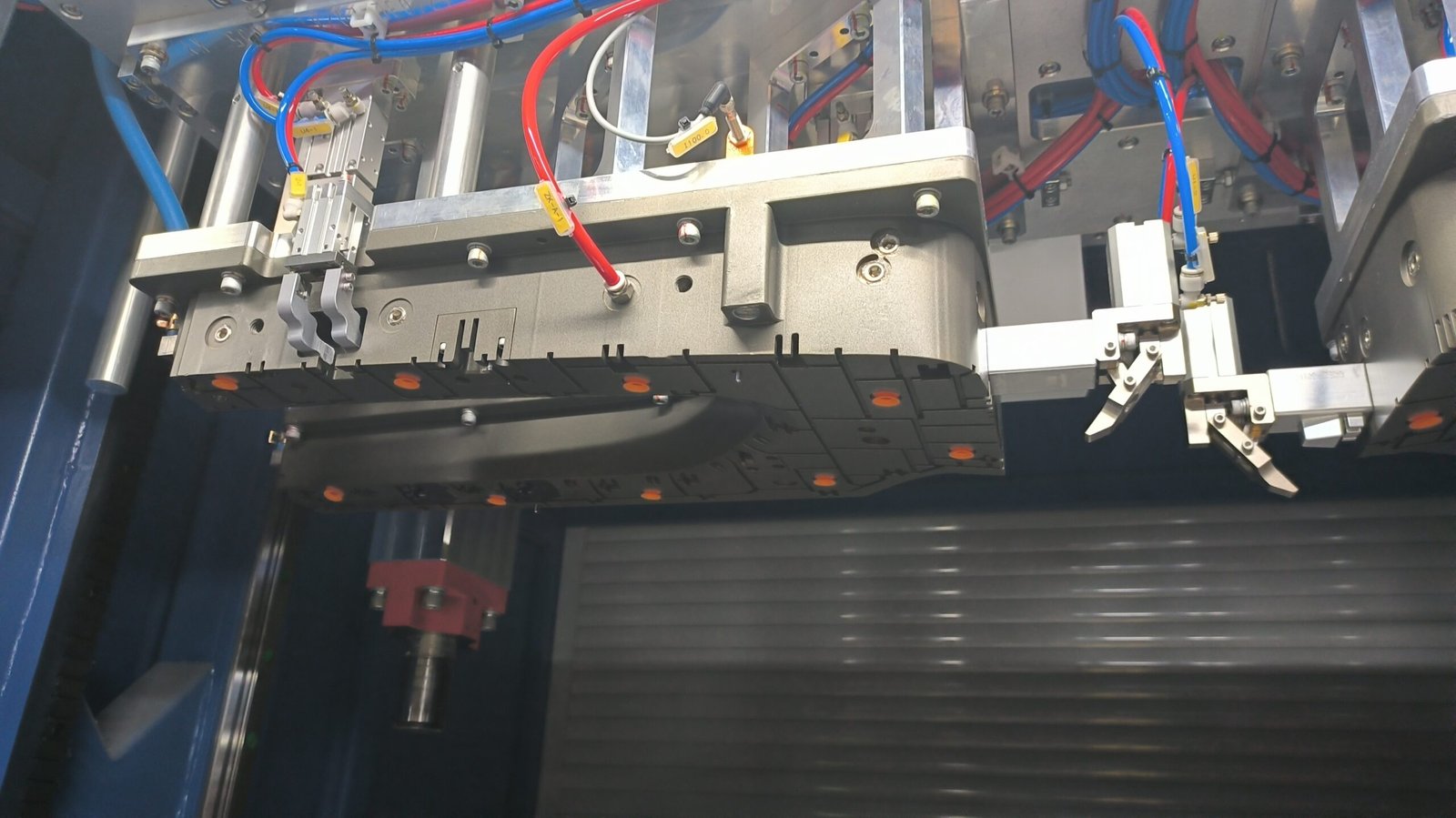

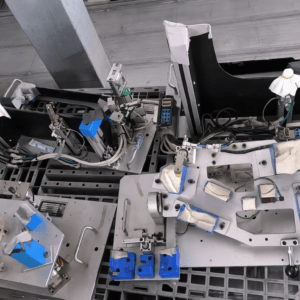

This automotive interior trim lamination equipment and fixtures are specifically designed for precision lamination of interior trim parts in passenger cars, commercial vehicles, and new energy vehicles. It is suitable for laminating various interior plastic and metal parts, including door panels, pillars, armrests, and center consoles. The equipment features an intelligent constant temperature control system and a precise pressure adjustment module, allowing for precise temperature control between 50℃ and 120℃, with a pressure error of ≤±0.1MPa. The fixtures utilize aerospace-grade aluminum substrate with a flexible silicone lamination head and an adaptive positioning clip structure, effectively avoiding problems such as wrinkling, bubbles, edge lifting, and lamination damage during the lamination process, achieving high adhesion and non-destructive lamination.

Both the equipment and fixtures adopt a modular quick-change design, supporting rapid switching between multiple vehicle models and interior trim specifications without complex debugging. This adapts to batch production line scenarios, improving lamination efficiency by more than 50% compared to traditional processes. The fixture surface is equipped with a scratch-resistant protective coating to prevent scratches on interior trim parts. The equipment features a built-in intelligent detection system that monitors bonding temperature, pressure, and time in real time, automatically alarming and shutting down in case of abnormalities, ensuring comprehensive product quality and operational safety. The entire system strictly complies with IATF 16949 automotive industry standards and the ISO 9001 quality system, possessing characteristics such as high and low temperature resistance, aging resistance, and high stability. It can be stably adapted to automotive interior trim production lines for extended periods, significantly reducing the defect rate of laminated coatings. It is a core piece of equipment for efficient quality control in the refined production process of automotive interior trim.

Reviews

There are no reviews yet.