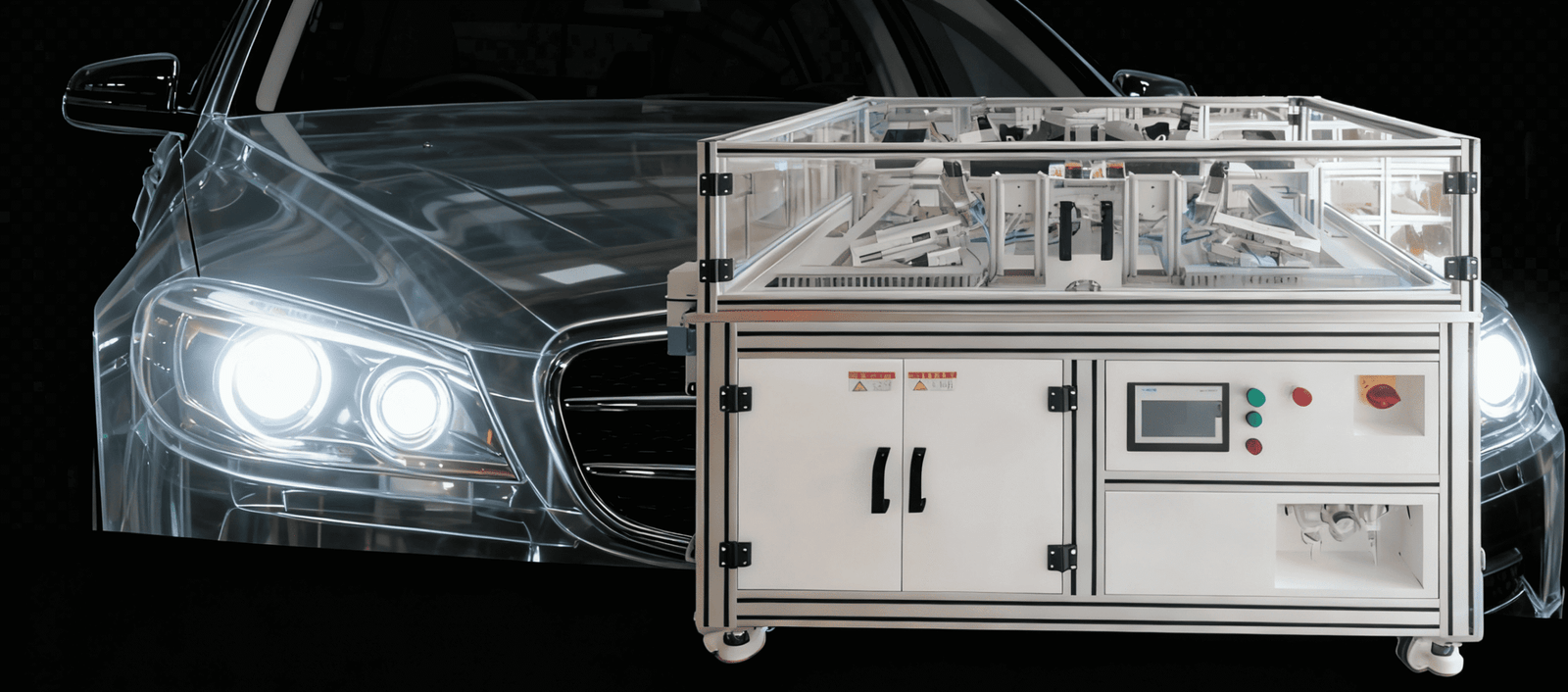

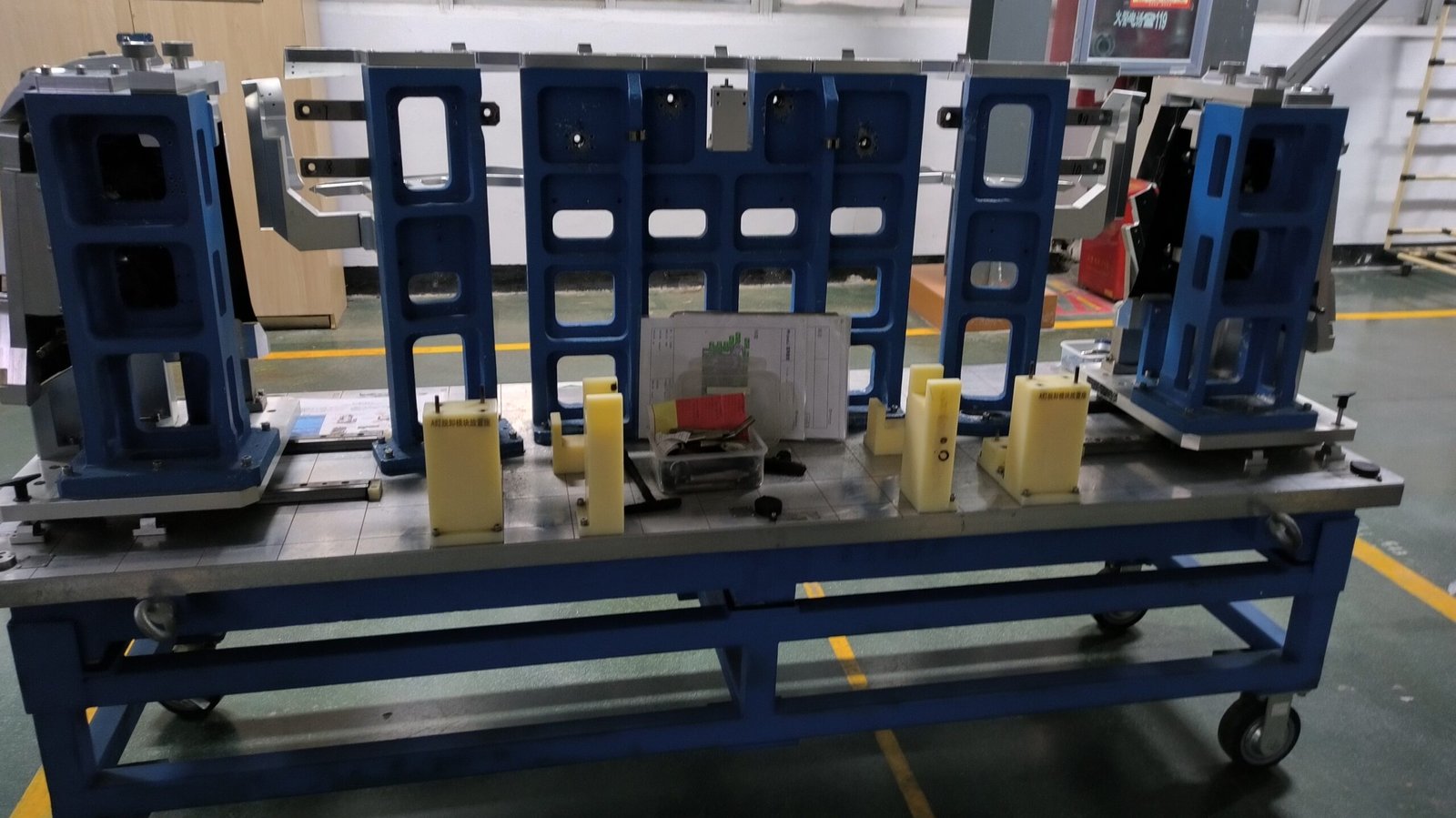

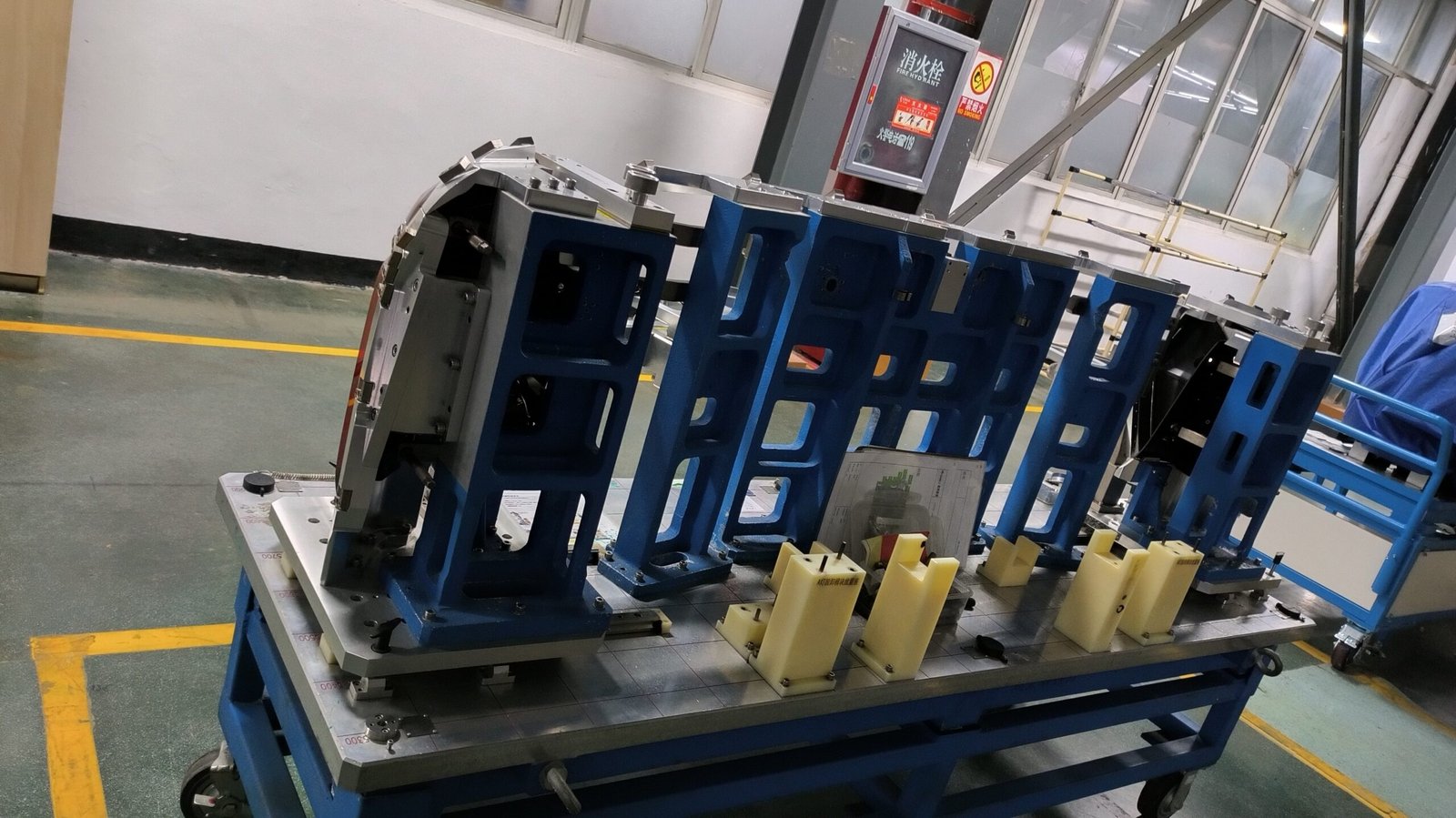

Description

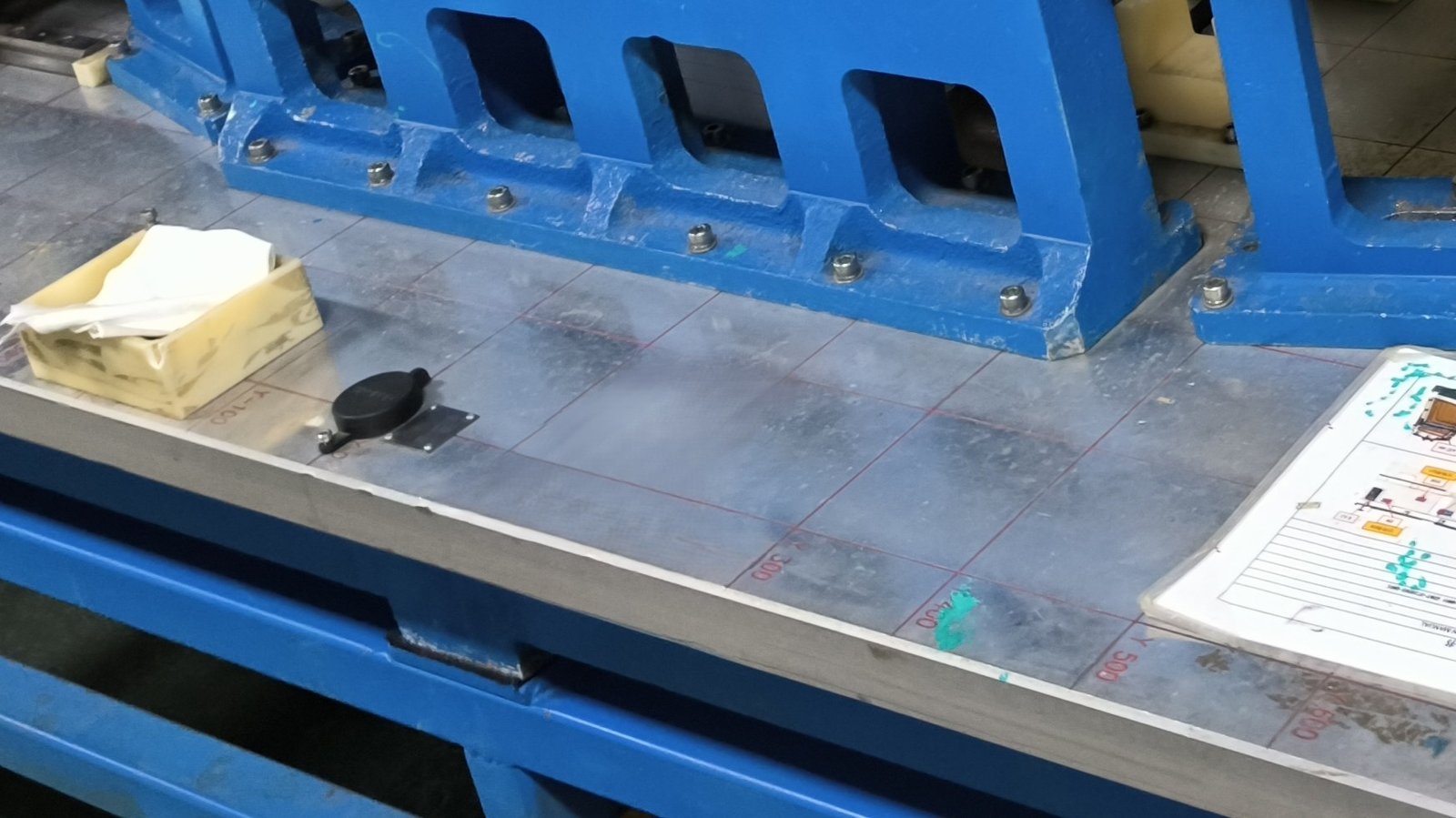

This automotive plastic exterior parts tooling system comprises core fixtures for the entire process, including assembly positioning, clamping and fastening, and precision cutting. It is specifically designed for the processing of plastic exterior parts for passenger cars, commercial vehicles, and new energy vehicles. The main body of the tooling is integrally molded from high-strength aerospace-grade aluminum, combined with scratch-resistant flexible pads and wear-resistant coatings, achieving a positioning accuracy of ±0.02mm. Equipped with adaptive positioning clamps and an intelligent pressure sensing system, it effectively avoids problems such as assembly misalignment, pressure damage, and exterior part deformation, achieving high-precision, non-destructive machining.

The entire tooling system adopts a modular quick-change structure, allowing for rapid switching between exterior parts of various models and specifications without complex debugging. It is suitable for mass production line operations, increasing overall production efficiency by over 45%. The core fixture has a built-in intelligent detection module that monitors key parameters such as processing pressure and positioning accuracy in real time, automatically alarming and stopping machine operation in case of abnormalities, comprehensively ensuring product quality and operational safety. The entire set of equipment strictly complies with the IATF 16949 automotive industry standard and the ISO 9001 quality management system. It has the characteristics of high and low temperature resistance (-40℃~85℃), UV resistance and aging resistance. It can be used stably for a long time in the automotive exterior parts production line, significantly reducing the processing defect rate. It is the core supporting equipment for the fine and mass production of automotive exterior parts.

Reviews

There are no reviews yet.