Description

Headlight Leveling Motor: Essential for Safe Driving & Regulatory Compliance

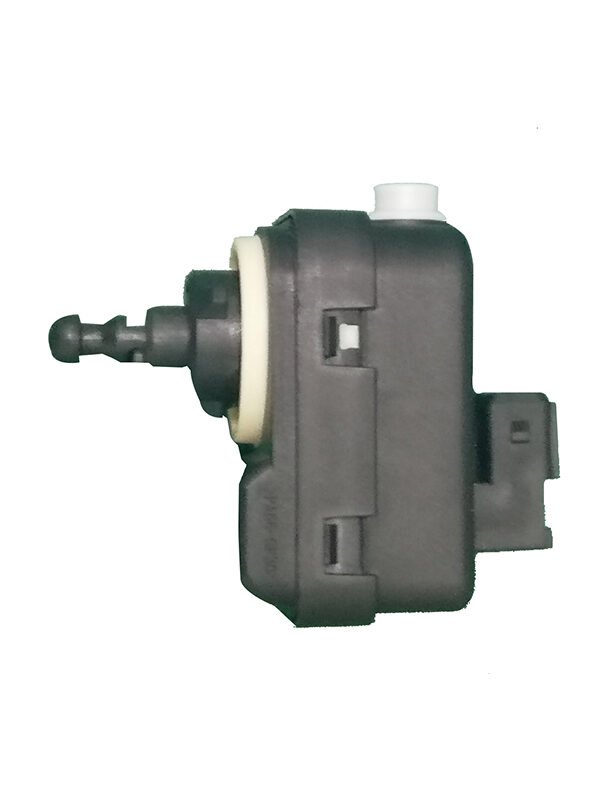

The headlight leveling motor is a pivotal component in modern vehicle lighting systems, designed to automatically adjust the height of headlight beams in real time. As vehicle load changes—such as when carrying passengers, loading cargo, or towing a trailer—the vehicle’s stance shifts, which can misalign the headlights. This misalignment either causes glare that endangers oncoming drivers or reduces forward visibility, compromising the driver’s ability to detect obstacles, pedestrians, or road hazards. The headlight leveling motor solves this critical issue by dynamically adjusting the beam angle, ensuring optimal illumination without disrupting other road users.

Constructed for durability and reliability, headlight leveling motors are engineered to withstand harsh automotive environments, including extreme temperatures (ranging from -40℃ to 125℃), vibration, moisture, and dust. Most models available on the market are either DC motors or stepper motors, tailored to 12V or 24V vehicle electrical systems. Stepper motor variants offer superior precision in beam adjustment, making them ideal for high-end vehicles or models with advanced driver assistance systems (ADAS), while DC motor versions provide cost-effective performance for mainstream vehicles. Equipped with precision gear transmissions, these motors deliver smooth, quiet operation and consistent adjustment accuracy, ensuring long-term stability even under frequent use.

Beyond enhancing driving safety, the headlight leveling motor is a mandatory component to meet global regulatory standards, including ECE R112 in Europe, FMVSS 108 in the United States, and corresponding regulations in Asia. Non-compliance with these standards can result in vehicle certification rejection, making the motor indispensable for automotive manufacturers. For vehicle owners, a malfunctioning headlight leveling motor not only risks safety but may also lead to fines during road inspections. Regular maintenance of the component—such as checking for wiring faults, gear jamming, or motor wear—ensures its continued functionality.

In addition to original equipment manufacturer (OEM) applications, headlight leveling motors are also in high demand in the aftermarket. They are essential for vehicle repairs, retrofits, or upgrades, especially for older vehicles being modified to meet modern safety standards. When selecting a headlight leveling motor, key considerations include compatibility with the vehicle’s make and model, motor type, voltage rating, and compliance with regional regulatory requirements. Choosing a high-quality motor ensures not only regulatory compliance but also peace of mind for drivers, knowing their headlights will perform optimally in all driving conditions.

Reviews

There are no reviews yet.