Description

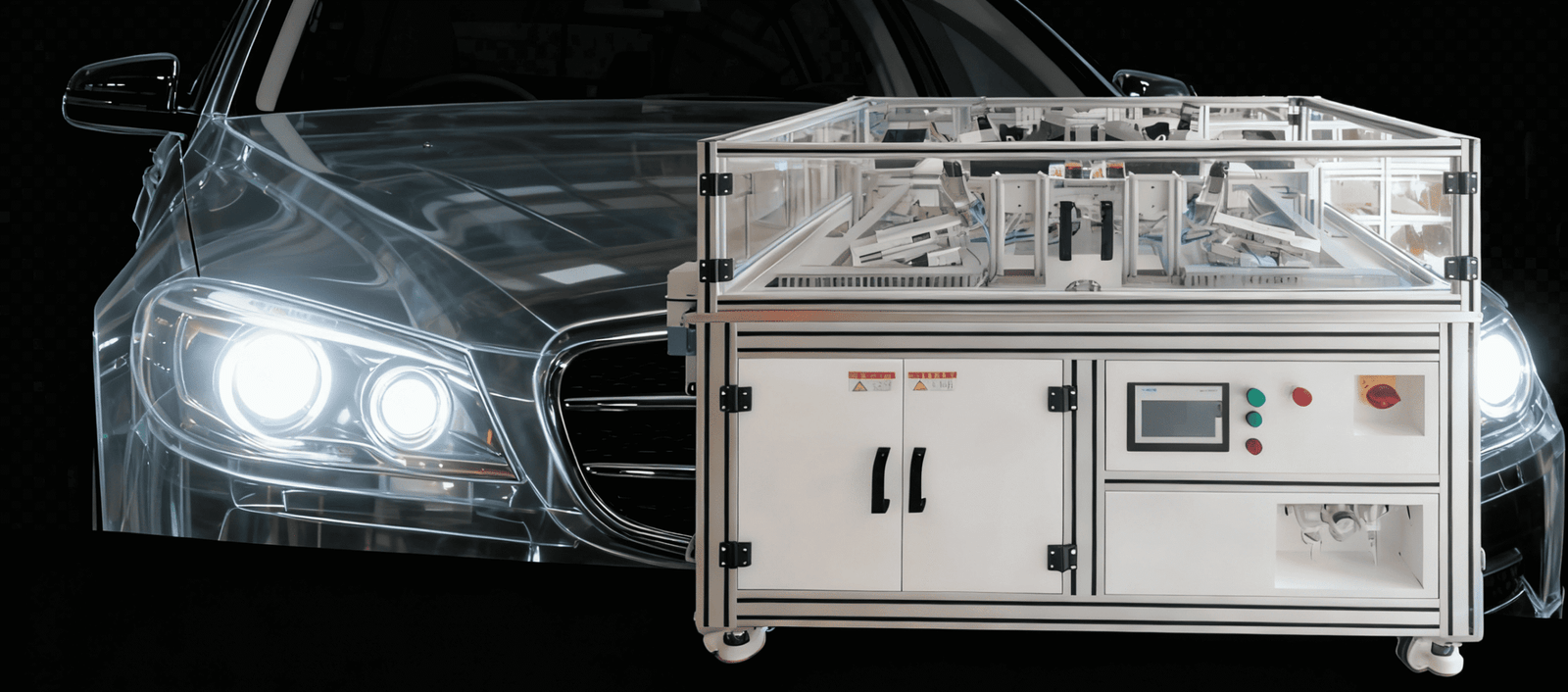

Automotive Headlight UV Curing Production Line: Efficiency, Precision & Eco-Friendliness for Modern Car Lamp Manufacturing

In the competitive automotive manufacturing industry, the quality and production efficiency of car headlights directly affect vehicle safety and market competitiveness. The automotive headlight UV curing production line has emerged as a core equipment solution, revolutionizing the curing process of headlight components with advanced UV technology. This production line integrates high efficiency, precision, and environmental protection, making it an indispensable choice for mainstream automakers and auto parts suppliers seeking to optimize production processes.

One of the core advantages of the UV curing production line for automotive headlights is its ultra-fast curing speed. Compared with traditional thermal curing methods that take hours, UV curing technology can complete the curing of adhesives, coatings, or sealants on headlight components in seconds to minutes. This drastic reduction in curing time shortens the entire production cycle of headlights by more than 60%, greatly improving factory throughput and reducing work-in-progress inventory. For mass-produced automotive headlights, this efficiency improvement directly translates into significant cost savings and faster time-to-market for products.

Precision is another key feature of this production line, which is crucial for the performance of automotive headlights. The UV curing system is equipped with high-precision optical components and intelligent control modules that ensure uniform UV light distribution. This uniform curing effect guarantees the stability of the bonding strength and sealing performance of headlight components, avoiding problems such as light leakage, fogging, or component detachment caused by uneven curing. Additionally, the production line supports customized adjustments for different headlight models and materials (such as PC, PMMA, and engineering plastics), adapting to the diverse needs of modern automotive lighting design.

Environmental protection and sustainability are also prominent advantages of the automotive headlight UV curing production line. UV curing materials (such as UV adhesives and coatings) do not contain volatile organic compounds (VOCs) and do not produce harmful emissions during the curing process, complying with global environmental standards such as EU REACH and US EPA. Unlike thermal curing, which consumes a lot of energy for heating, UV curing only requires electricity to drive the UV light source, reducing energy consumption by more than 70%. This not only helps factories reduce carbon footprints but also lowers long-term energy costs.

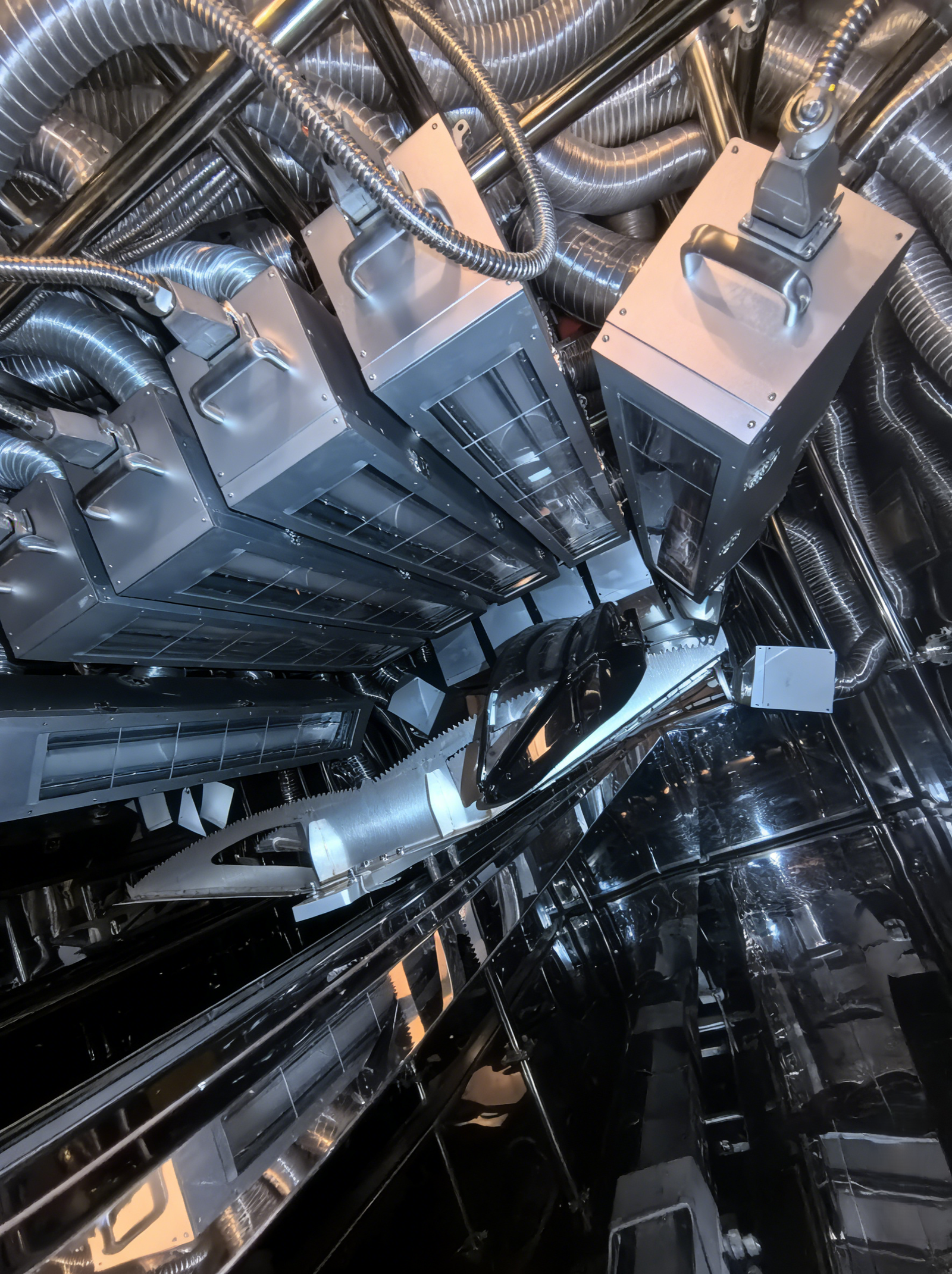

Moreover, the production line is equipped with a full set of intelligent monitoring and safety protection systems. Real-time monitoring of UV light intensity, curing time, and component positioning ensures consistent product quality. Safety features such as UV light shields, emergency stop buttons, and automatic alarm systems effectively protect operators from UV radiation and ensure production safety. The modular design of the production line also facilitates later maintenance, upgrades, and expansion, enhancing the flexibility and long-term value of the equipment.

In conclusion, the automotive headlight UV curing production line meets the modern automotive industry’s demands for high efficiency, precision, and environmental protection. By adopting this advanced production solution, automakers can significantly improve product quality, optimize production processes, and gain a competitive edge in the market. As automotive lighting technology continues to evolve (such as the popularization of LED headlights), the UV curing production line will be further upgraded to adapt to more complex production requirements, driving the continuous development of the automotive lighting manufacturing industry.

Reviews

There are no reviews yet.