Description

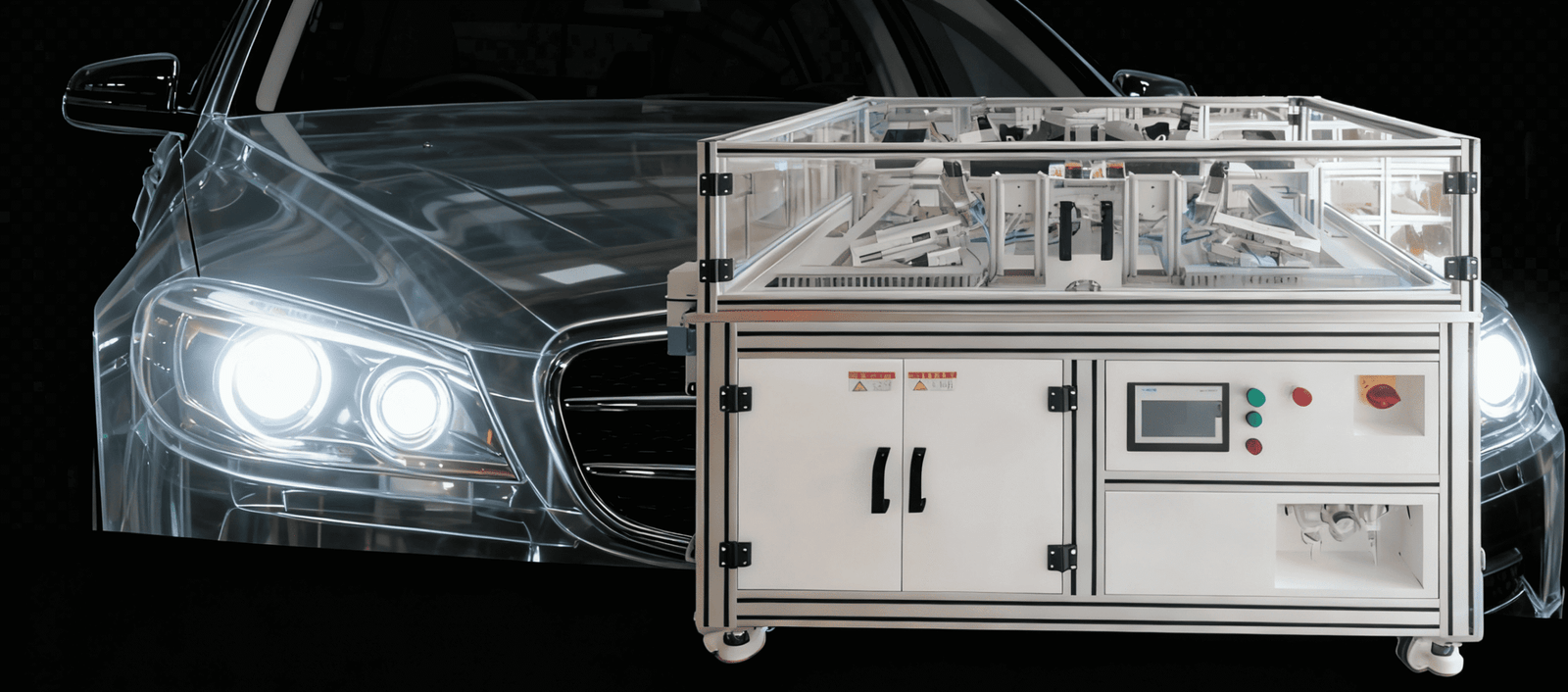

This positioning fixture is specifically designed for the precise assembly of plastic components in lighting systems for passenger cars, commercial vehicles, and new energy vehicles. It is suitable for positioning various automotive lighting plastic parts, such as lamp covers, housings, lenses, and decorative rings. The fixture is made of aerospace-grade aluminum alloy and coated with a scratch-resistant POM layer, offering positioning accuracy up to ±0.01mm. Equipped with an adaptive positioning system and anti-offset buckle structure, it effectively prevents misalignment and scratches during the assembly of plastic parts.

The modular quick-change design supports rapid switching between different vehicle models, adapting to mass assembly scenarios on production lines and increasing positioning efficiency by more than 35%. This product strictly complies with IATF 16949 automotive industry standards and the ISO 9001 quality system. It features high and low temperature resistance (-40℃ to 85℃) and anti-aging properties, ensuring consistent assembly posture of automotive lighting plastic parts and significantly reducing defects such as looseness and misalignment. It is a core positioning device for efficient quality control on automotive lighting assembly lines.

Reviews

There are no reviews yet.